Filtration And Separation

.webp/:/cr=t:4.91%25,l:0%25,w:100%25,h:90.19%25/rs=w:600,h:800,cg:true)

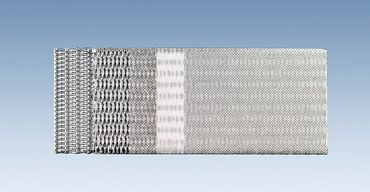

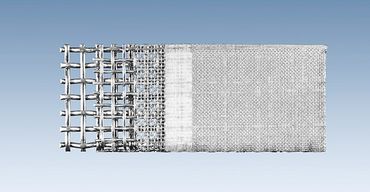

BOPP manufactures a comprehensive and diverse range of medium, fine and ultra-fine filter meshes. These are produced using state-of-the-art weaving machines, in clean and air-conditioned halls, to the highest levels of quality and reproducibility. A growing number of sintered meshes are now available to meet the challenges of increasingly demanding applications. These consist of two or more layers of mesh crafted into laminates using heat and pressure. Dependent upon requirements, both meshes and sintered products can be converted into dimensionally accurate components and semi-finished goods, with individual items carefully worked by hand and series production either partly or fully automated using special machinery designed expressly for this purpose.

Properties

General properties for the filtration industry

- Raw materials compliant with the highest international standards

- Manufactured using state-of-the-art production processes

- Precise aperture size distribution

- Uniform surface area for improved processes and cleaning

- High levels of abrasion resistance, no particle detachment

- Developed using many years of experience in filtration

- High-value filtration results thanks to professional manufacturing

The Most Important Characteristics of Filtration Process

Requirements Are

- Loadings in use: mechanical, thermal, chemical

- Compression ratios

- Flow rates

- Mass, dimensions, design

- Installation location

- Accessories

- Cleanliness requirements

- Ergonomics in use

- Standards requirements

The Most Important Considerations to Meet Demanding Filtration Requirements Are

- The correct choice of the most suitable materials

- Deciding between filter mesh or sintered product

- Wire diameter, especially for filter meshes

- Aperture count, mesh count

- Filter fineness

- Mesh style, geometry, or laminate type

- Tensile yield point

- Workability

- Binding method

Copyright © 2022, Rocky Mountain Process Components, LLC. All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.